Great success for Pulsar Industry present with its huge experience in the field of production process design, factory, department and line layouts.

Pulsar Industry also took part in the 2022 edition of IFFA, the most important international trade fair dedicated to the meat industry, held in Frankfurt from 14 to 19 May.

Pulsar Industry has been active in meat production and processing sector for more than thirty years, and as well as proposing a range of innovative solutions to production and packaging departments, its consultants are also at the customers’ disposal right from the early stages of definition or review of production processes.

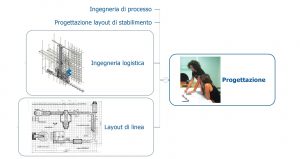

Design requires in-depth analysis on customer’s goals; thanks to their expertise in mechanics, automation, robotics and IT, Pulsar Industry technicians are able to manage all phases of development, from the idea to the final design, continuously intertwining their path with the customer’s expectations.

robotics and IT, Pulsar Industry technicians are able to manage all phases of development, from the idea to the final design, continuously intertwining their path with the customer’s expectations.

They never give up until simple and innovative solutions with a short ROI are found.The support of the customer in the definition of the processes has the purpose of making them easily automated and improve efficiency.

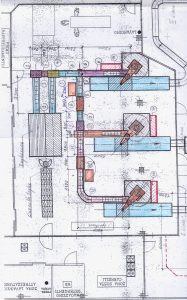

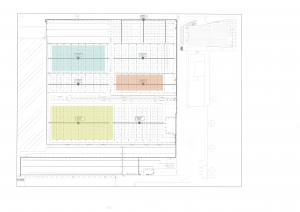

Hence, Pulsar Industry experts work in the design of line, department and factory layout. Significant attention is paid

to logistics engineering, which is fundamental to get particularly efficient storage and handling systems.

All Pulsar Industry’s design proposals are, finally, integrated by Dynamic, the departmental software for production control and operational management of warehouse logistics entirely designed and developed by Pulsar’s IT experts.

All Pulsar Industry’s design proposals are, finally, integrated by Dynamic, the departmental software for production control and operational management of warehouse logistics entirely designed and developed by Pulsar’s IT experts.

Dynamic is equipped with all the functions necessary to govern the production process in the food industry, from planning to dispatch through the phases of reception, processing, seasoning, packaging and logistics.

Dynamic allows continuous and highly automated monitoring of all field variables that contribute to achieving high productivity while respecting the criteria of efficiency in the use of energy resources (electricity, heat, refrigeration systems). Using Dynamic, Pulsar Industry’s customers (Amadori, Beretta, Bordoni, Conserve Italia, Grandi Salumifici Italiani, PAC2000A, Parmareggio, and Rovagnati, to name some but few) are able to line out the improvements areas of their plants thanks to the Overall Equipment Effectiveness – OEE index. This is the first, crucial step to increase marginality.

refrigeration systems). Using Dynamic, Pulsar Industry’s customers (Amadori, Beretta, Bordoni, Conserve Italia, Grandi Salumifici Italiani, PAC2000A, Parmareggio, and Rovagnati, to name some but few) are able to line out the improvements areas of their plants thanks to the Overall Equipment Effectiveness – OEE index. This is the first, crucial step to increase marginality.