Dynamic software, less costs to produce

Dynamic, Pulsar Industry production and warehouse management software, grants full efficiency and productivity control

2012 has just begun and Pulsar Industry, young and dynamic company of Modena, has been present in the automation and IT marketplace mainly targeting the food industry for over 20 years, has already started some installation of its leading product, Dynamic departmental software.

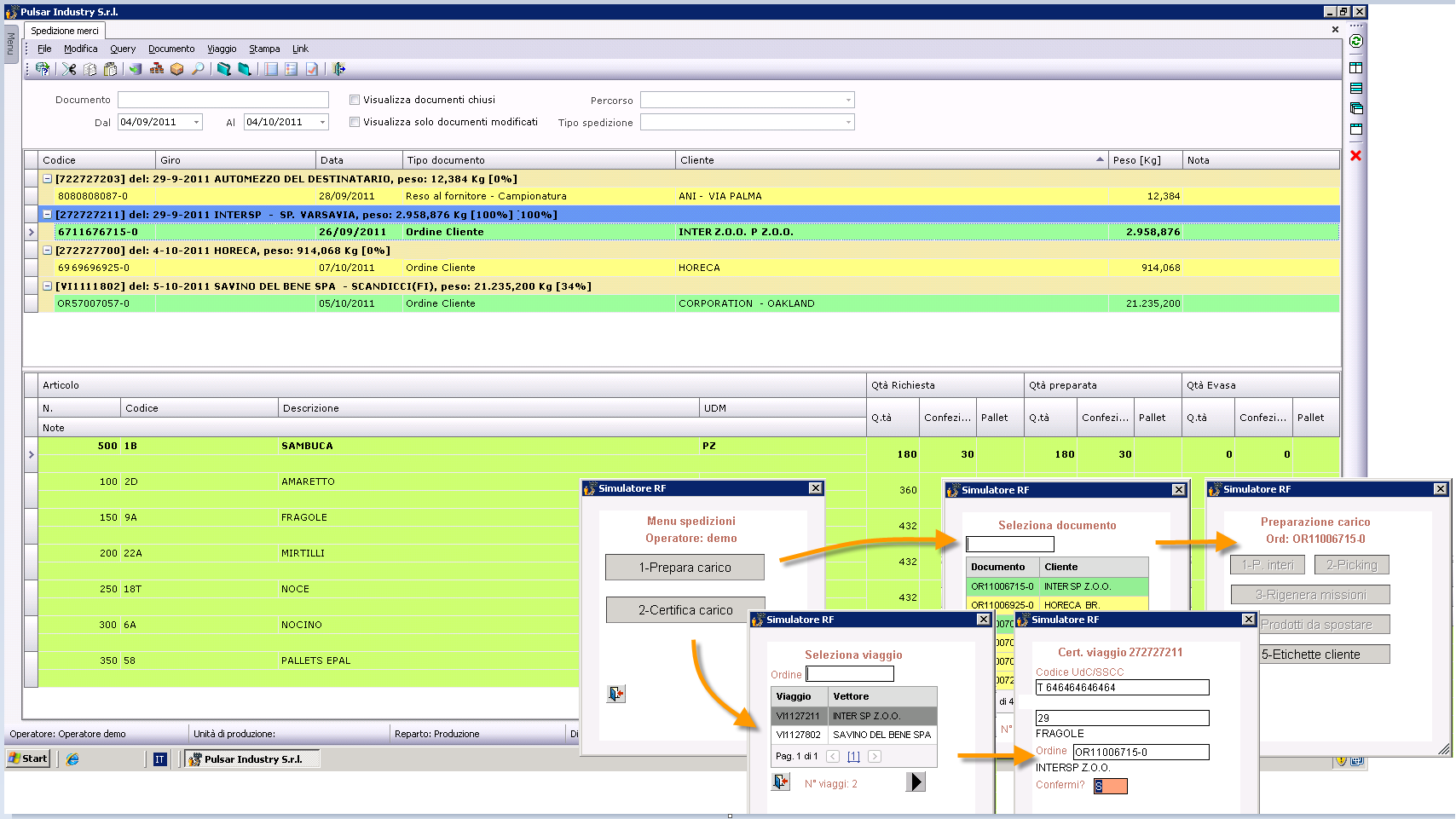

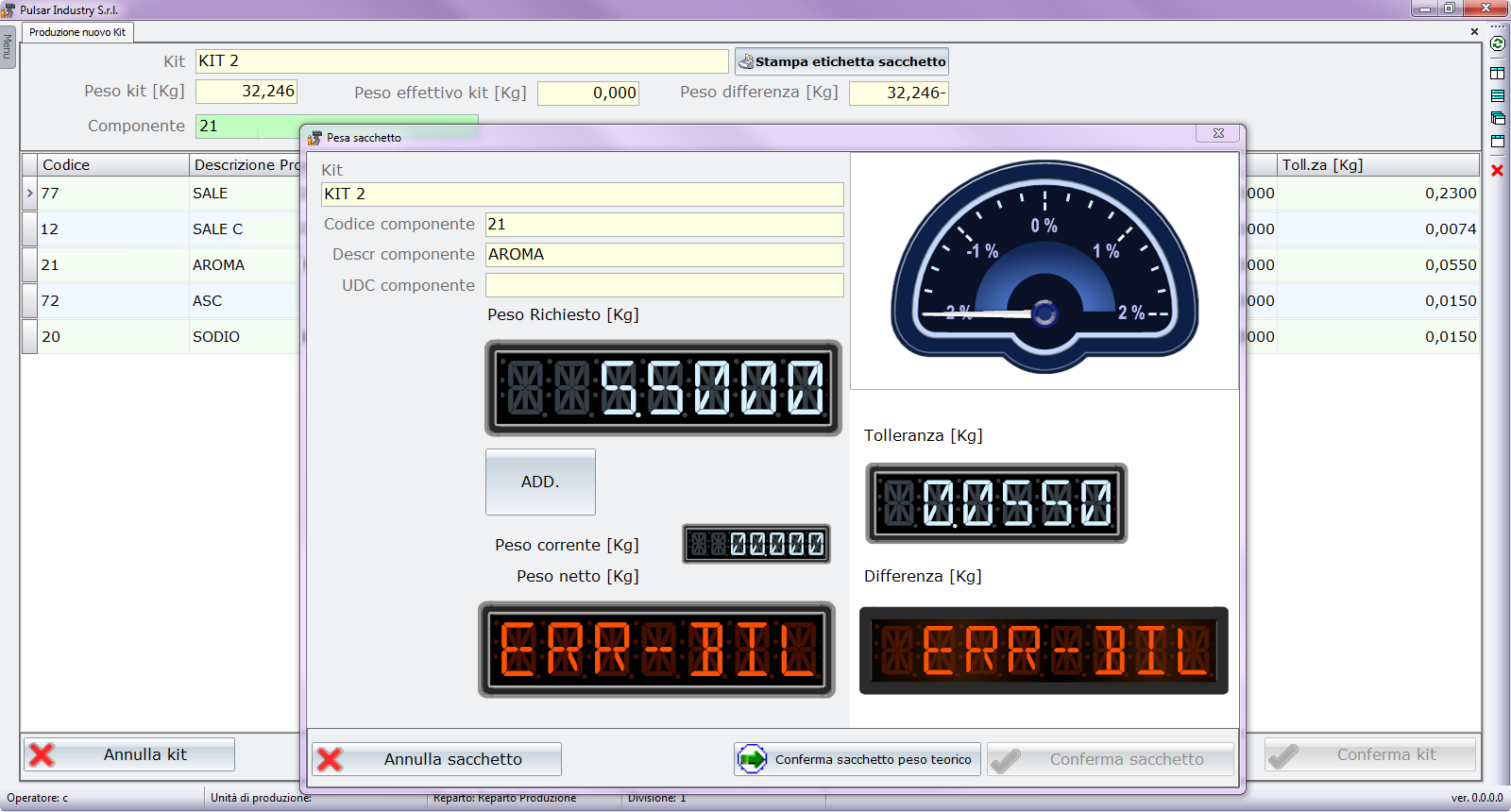

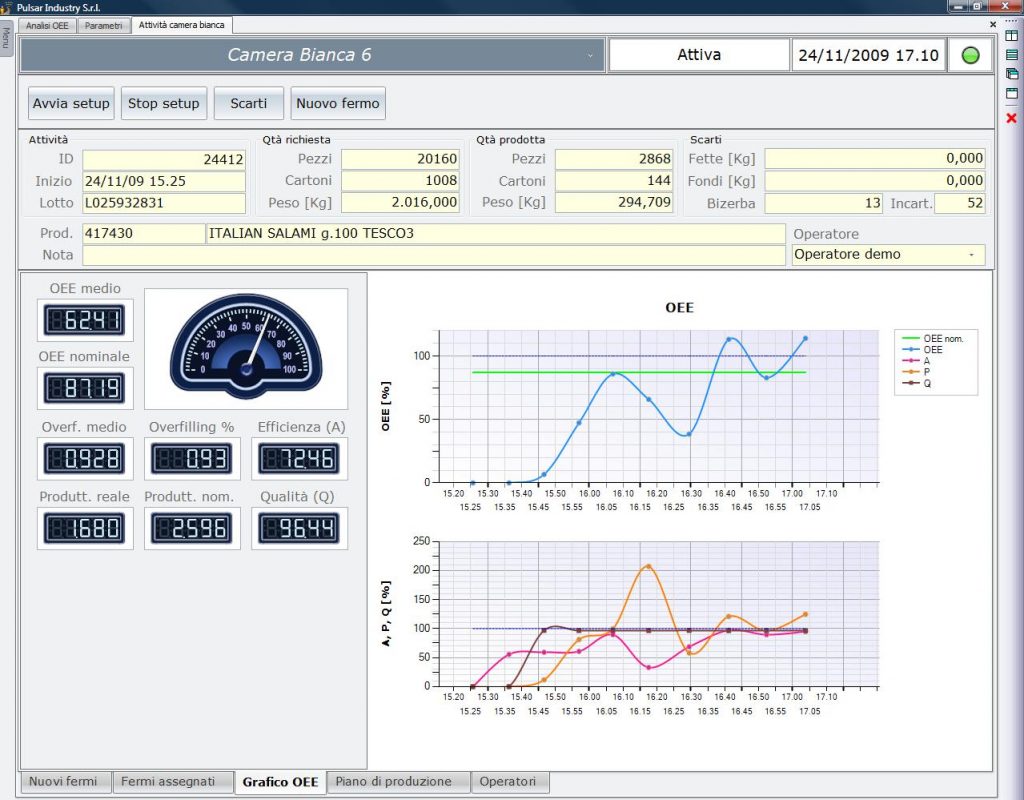

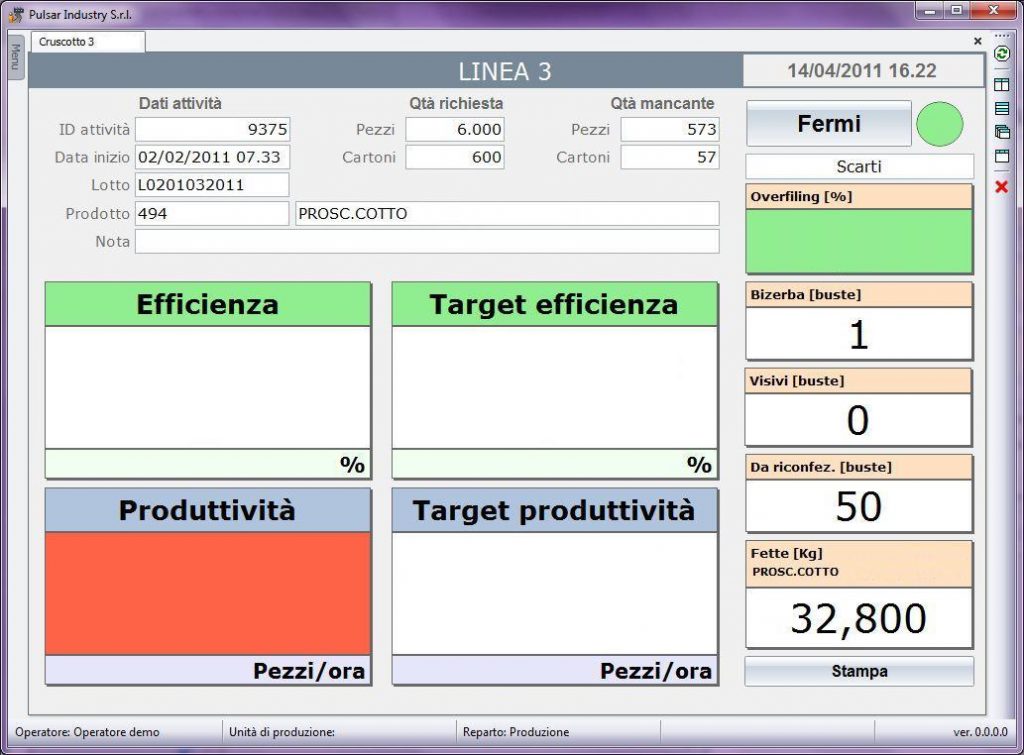

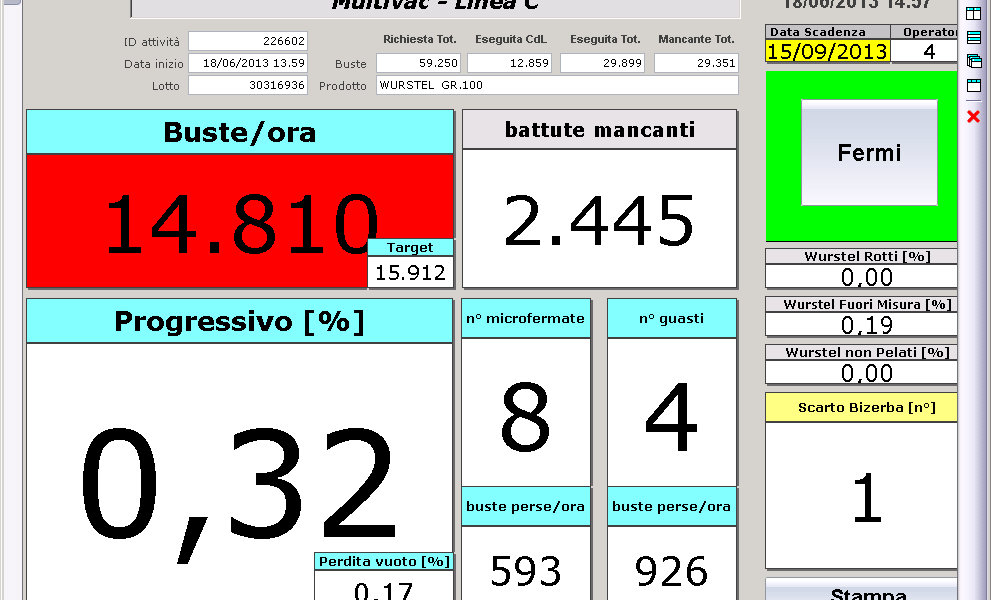

Dynamic, departmental software for the production management and operative warehouse management, entirely designed and produced by Pulsar Industry engineers, has always been one of the company’s main points of strength. The 2012 version of Dynamic upgraded version of Dynamic, enriched with increasingly powerful and incisive monitoring capabilities of the basic production parameters.

Dynamic enables to fully control any problem of batch tracking in a simple and effective way: from any information, it is possible to trace back any production batch, the providers who contribute to its productionprocess and also all the final customers. In addition, they can be easily organized and connected with the most significant event of the production process. Most data entries can be automatically filled by gathering the necessary data on the field through special probes interconnected by means of the plant control network.

Moreover, Dynamic can also read and compare all function data in such a way as to provide graphics of the variances, from efficiency and productivity parameters in real time. This is just the area where Pulsar Industry has invested in product development most. Market difficulty has companies gain deeper knowledge of their own production processes and efficiency. Thanks to Overall Equipment Effectiveness(OEE), the Pulsar Industry’s customers already using Dynamic can detect their processes areas that can be developed: this is the first, crucial step to increase marginality.

Dynamic is applied in a growing number of market sectors, such as: meat processing industry, other food production sectors and bottling processes. Big industrial groups and small-sized enterprises alike have had significant benefits from large and systematic application of Dynamic and its powerful production and logistic process control and management functions.

![]()