Pulsar Industry has been selected by HIT – Hub Innovazione Trentino among the protagonists of the 2022 edition

The Hub Innovazione Trentino Foundation (HIT) is an instrumental body of the Autonomous Province of Trento and a research and knowledge dissemination organization in accordance with the discipline of the European Union. HIT promotes and enhances the scientific-technological research activities and results of its founders: University of Trento, Edmund Mach Foundation, Bruno Kessler Foundation and Trentino Sviluppo.

The Hub Innovazione Trentino Foundation (HIT) is an instrumental body of the Autonomous Province of Trento and a research and knowledge dissemination organization in accordance with the discipline of the European Union. HIT promotes and enhances the scientific-technological research activities and results of its founders: University of Trento, Edmund Mach Foundation, Bruno Kessler Foundation and Trentino Sviluppo.

The Industrial AI Challenge is an initiative that allows the selected companies to discover and test the benefits of Artificial Intelligence for analysis and optimization of industrial production processes thanks to the involvement of seven groups of students that, in two months’ time, will be performing advanced statistical analyses and, applying Machine Learning techniques, creating predictive models based on the data provided by the selected companies.

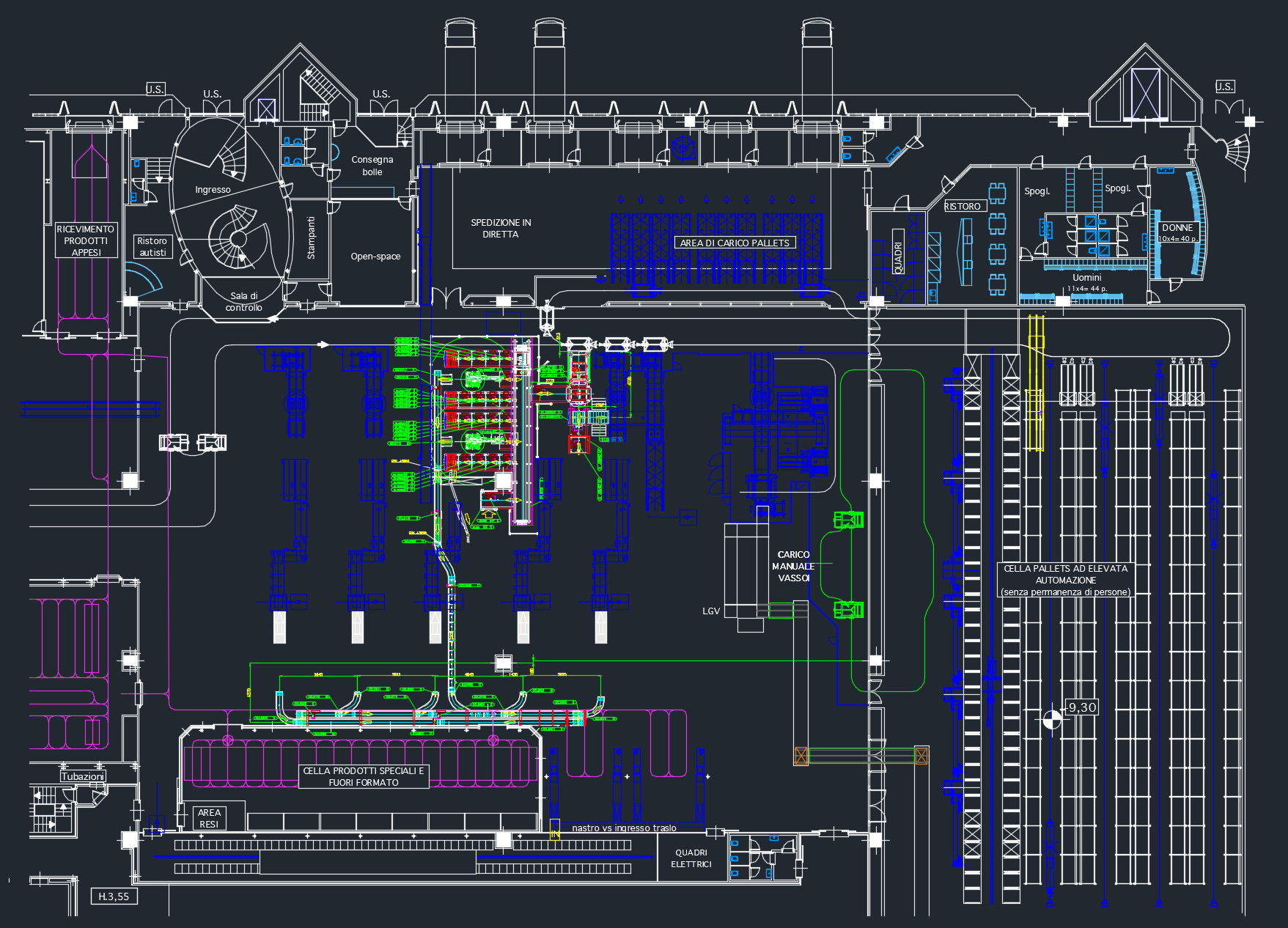

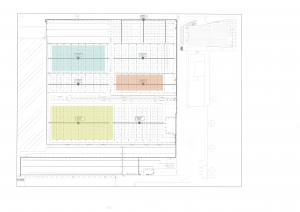

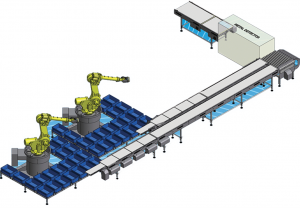

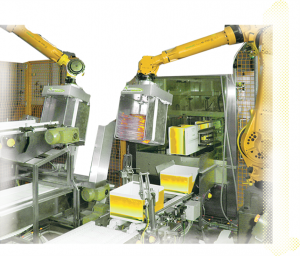

Pulsar Industry, with offices in Spilamberto (Modena) and Rovereto (Trento) offers complete industrial automation and factory software solutions for the food industry through the design and manufacturing of automatic / robotic systems for the process, packaging, storage and shipping of final product.

Pulsar Industry presents a challenge aimed to produce an AI model that enables selecting the best semi-finished product for feeding the slicing lines to obtain minimum waste and increase productivity, thus improving the OEE index.

Pulsar Industry is a young and dynamic company. Born in the mid-1980s, has grown over time to reach the current 70 people. The main strength of the company is the multiplicity of skills that allows it to address all aspects related to the implementation of innovative solutions with high technological content for its customers.

All phases of design and realization of the mechanics, automation and logistics process management software take place completely within the company without the need for external suppliers. This results in integrated projects where simplicity of solution, cleanliness and efficiency benefit the customer, who has a single, competent, and highly motivated partner.

Pulsar Industry’s customers (Amadori, Beretta, Conserve Italia, Grandi Salumifici Italiani, and Rovagnati, to name some but few) operate in the food industry, where strict requirements for quality control and traceability are present, but where, at the same time, it is increasingly important to seek the best in terms of quality, efficiency and, ultimately, marginality.

robotics and IT, Pulsar Industry technicians are able to manage all phases of development, from the idea to the final design, continuously intertwining their path with the customer’s expectations.

robotics and IT, Pulsar Industry technicians are able to manage all phases of development, from the idea to the final design, continuously intertwining their path with the customer’s expectations. All Pulsar Industry’s design proposals are, finally, integrated by Dynamic, the departmental software for production control and operational management of warehouse logistics entirely designed and developed by Pulsar’s IT experts.

All Pulsar Industry’s design proposals are, finally, integrated by Dynamic, the departmental software for production control and operational management of warehouse logistics entirely designed and developed by Pulsar’s IT experts. refrigeration systems). Using Dynamic, Pulsar Industry’s customers (Amadori, Beretta, Bordoni, Conserve Italia, Grandi Salumifici Italiani, PAC2000A, Parmareggio, and Rovagnati, to name some but few) are able to line out the improvements areas of their plants thanks to the Overall Equipment Effectiveness – OEE index. This is the first, crucial step to increase marginality.

refrigeration systems). Using Dynamic, Pulsar Industry’s customers (Amadori, Beretta, Bordoni, Conserve Italia, Grandi Salumifici Italiani, PAC2000A, Parmareggio, and Rovagnati, to name some but few) are able to line out the improvements areas of their plants thanks to the Overall Equipment Effectiveness – OEE index. This is the first, crucial step to increase marginality.

partments for the handling of portioned meat and semi-processed products, and robotized palletizing plants for pallet making for finished product storage. It is also possible to carry out integrated analysis on manpower, energy consumption, other industrial expenses, machine stops at any work cycle, and production efficiency basing on Overall Equipment Effectiveness – OEE index.

partments for the handling of portioned meat and semi-processed products, and robotized palletizing plants for pallet making for finished product storage. It is also possible to carry out integrated analysis on manpower, energy consumption, other industrial expenses, machine stops at any work cycle, and production efficiency basing on Overall Equipment Effectiveness – OEE index.